Value Stream Mapping Verspillingen inzichtelijk (+ template) Bureau Tromp

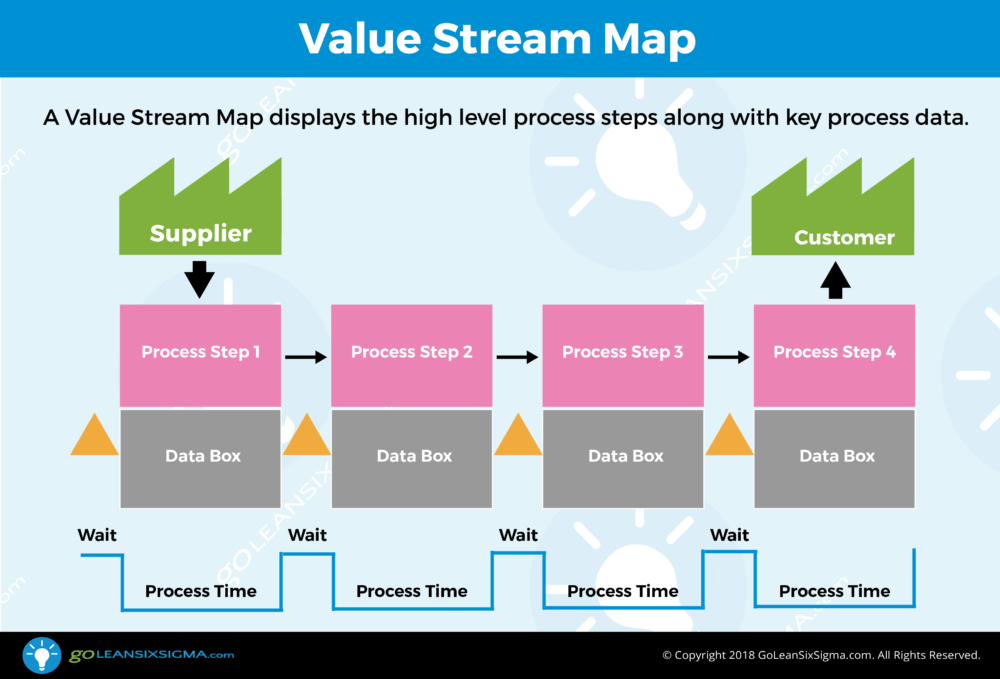

Value stream mapping is a flowchart method to illustrate, analyze and improve the steps required to deliver a product or service. A key part of lean methodology, VSM reviews the flow of process steps and information from origin to delivery to the customer. As with other types of flowcharts, it uses a system of symbols to depict various work.

The Ultimate Guide to Value Stream Mapping by Creately Thousand Words by Creately Medium

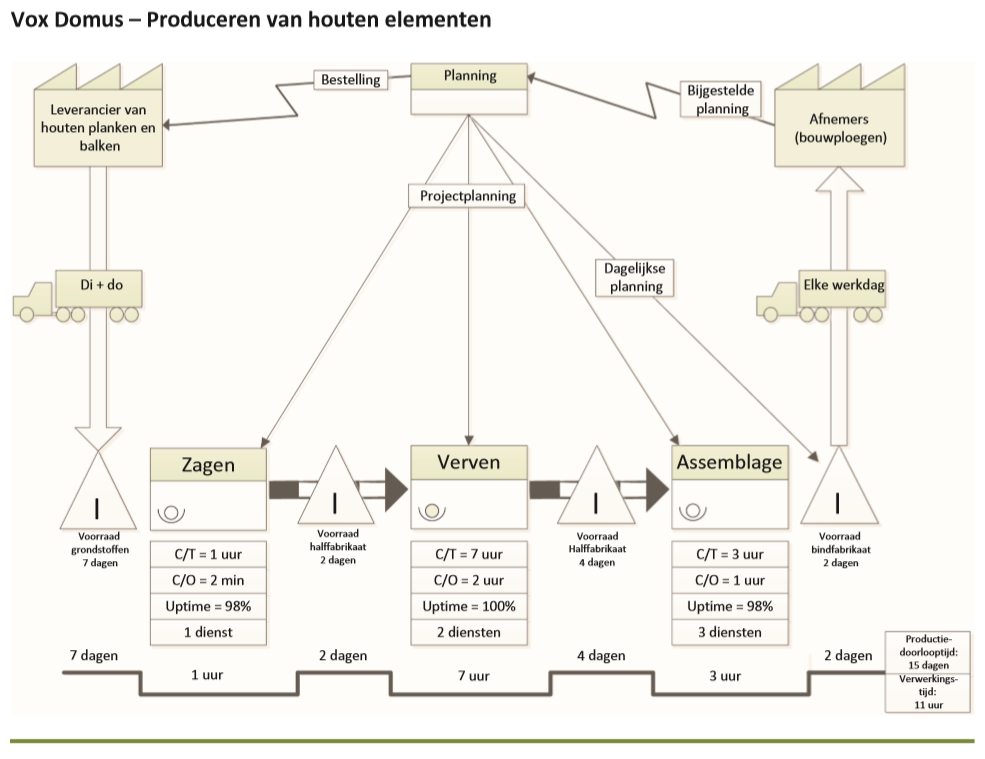

Value Stream Mapping (VSM) is een waardevolle stap in het verbeterproces. Want het laat zien wat in je proces waarde toevoegt. Met een voorbeeld leggen we uit hoe een Value Stream Map je productieproces kan stroomlijnen en je verbeterdoelen helpt bereiken. - de klant, rechtsbovenin, als spil in de kring. - de leveranciers, linksboven.

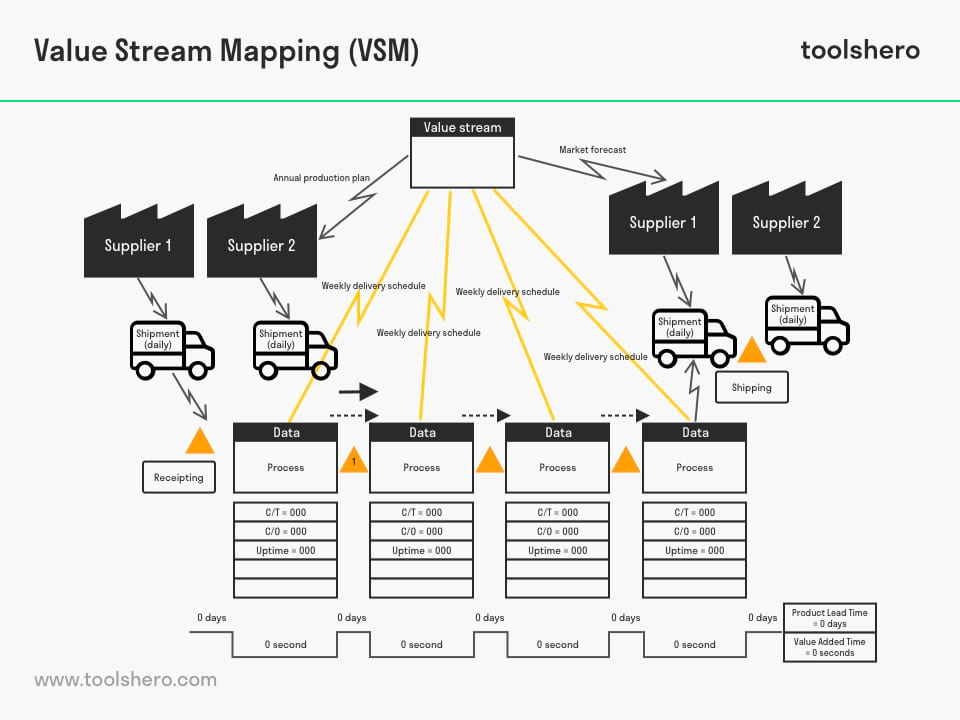

Value Stream Mapping Free Template

Value stream mapping (sometimes called VSM) is a lean manufacturing technique to analyze, design, and manage the flow of materials and information required to bring a product to a customer. Also known as "material and information-flow mapping", it uses a system of standard symbols to depict various work streams and information flows.

Value Stream Map voor Buddy Netwerk Lean Six Sigma Groep

Value stream mapping is a lean tool that documents the step-by-step processes required to bring a product or service to market. It helps visualize, analyze, and improve all the steps involved by identifying waste and reducing process cycle times. The ultimate goal of VSM is to create more value for customers while improving overall efficiency.

Value Stream Map Lean Six Sigma Groep

The ITIL ® 4 Foundation publication defines a value stream as a series of steps an organization undertakes to create and deliver products and services to consumers. Value stream maps are also one of the tools from Lean manufacturing. VSM visualizes the flow of a single product or service from supplier to customer, with the aim of identifying.

10 Easy Steps to Complete a Value Stream Map (VSM)

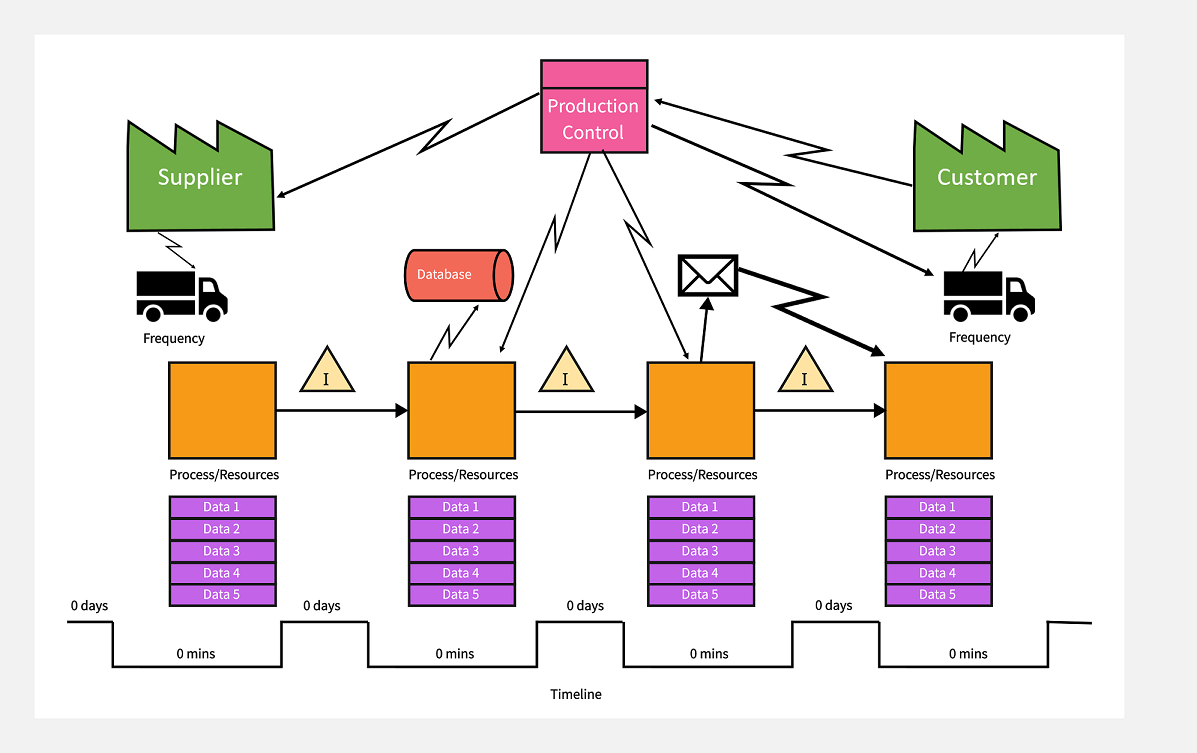

Figuur 1: Value Stream Mapping voorbeeld. NB: Als je je diagram in Lucidchart maakt, kun je het beste onze sjabloon voor een value stream-overzicht gebruiken of onze vormbibliotheek voor value streams toevoegen. Klik gewoon op 'Meer vormen' onderaan in de editor en schakel het selectievakje 'Value stream' in. 1.

What is Value Stream Mapping? How to Create a Value Stream Mapping in 8 Easy Steps Creately

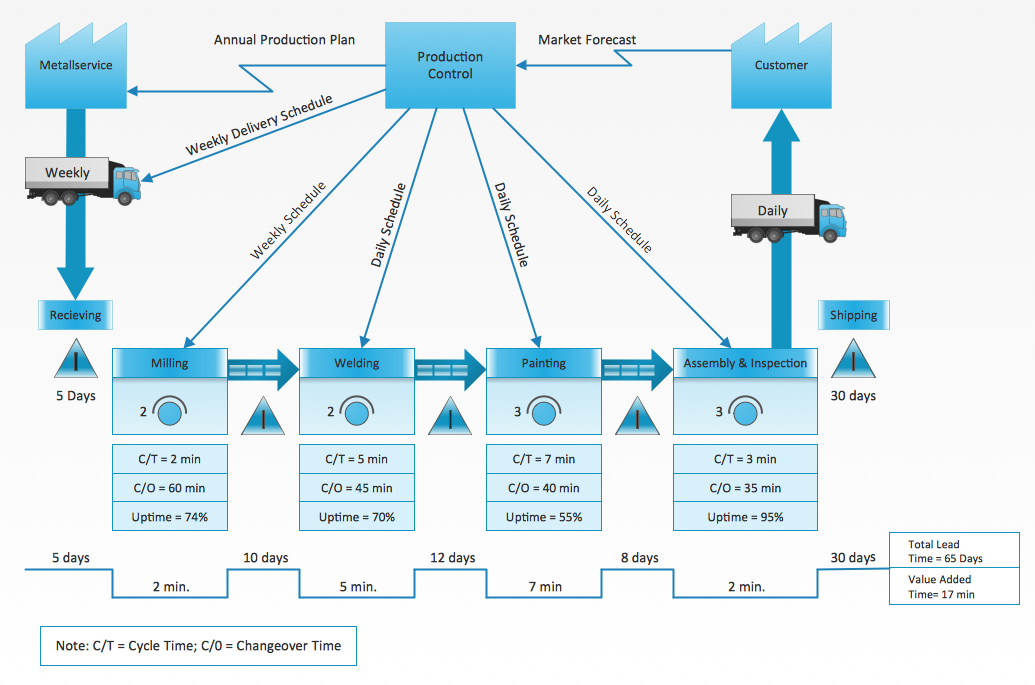

A Value Stream Map (VSM) visually displays the flow of steps, delays and information required to deliver a product or service to the customer. Value Stream Mapping allows analysis of the Current State Map in terms of identifying barriers to flow and waste, calculating Total Lead Time and Process Time and understanding Work-In-Process.

De value stream map Boom Management

Definition, Working, and Examples. Value stream mapping (VSM) shows the events leading up to product usage to map inputs vs. outputs and reduces waste. Chiradeep BasuMallick Technical Writer. September 20, 2022. Value stream mapping (VSM) is a project workflow visualization tool that pictorially represents the events that lead to the user.

Value Stream Map VSM

History of value stream mapping. The first version of the VSM was developed in the Toyota Production System (TPS) back in the 40s, but only later transformed into the tool that we know today. The earliest versions of VSMs were quite complex and industry-oriented (and it still holds a huge industry interest today).

Streamline Your Processes with Value Stream Mapping in 2023

A value stream is a set of actions that help a company identify areas of value that will in turn increase the value service or product has to the customer. The purpose of a value stream is to eliminate waste and identify bottlenecks to improve the overall efficiency of a process or service. Value streams always begin and end with the customer.

Value Stream Map Kaufman Global Lean and Operational Excellence

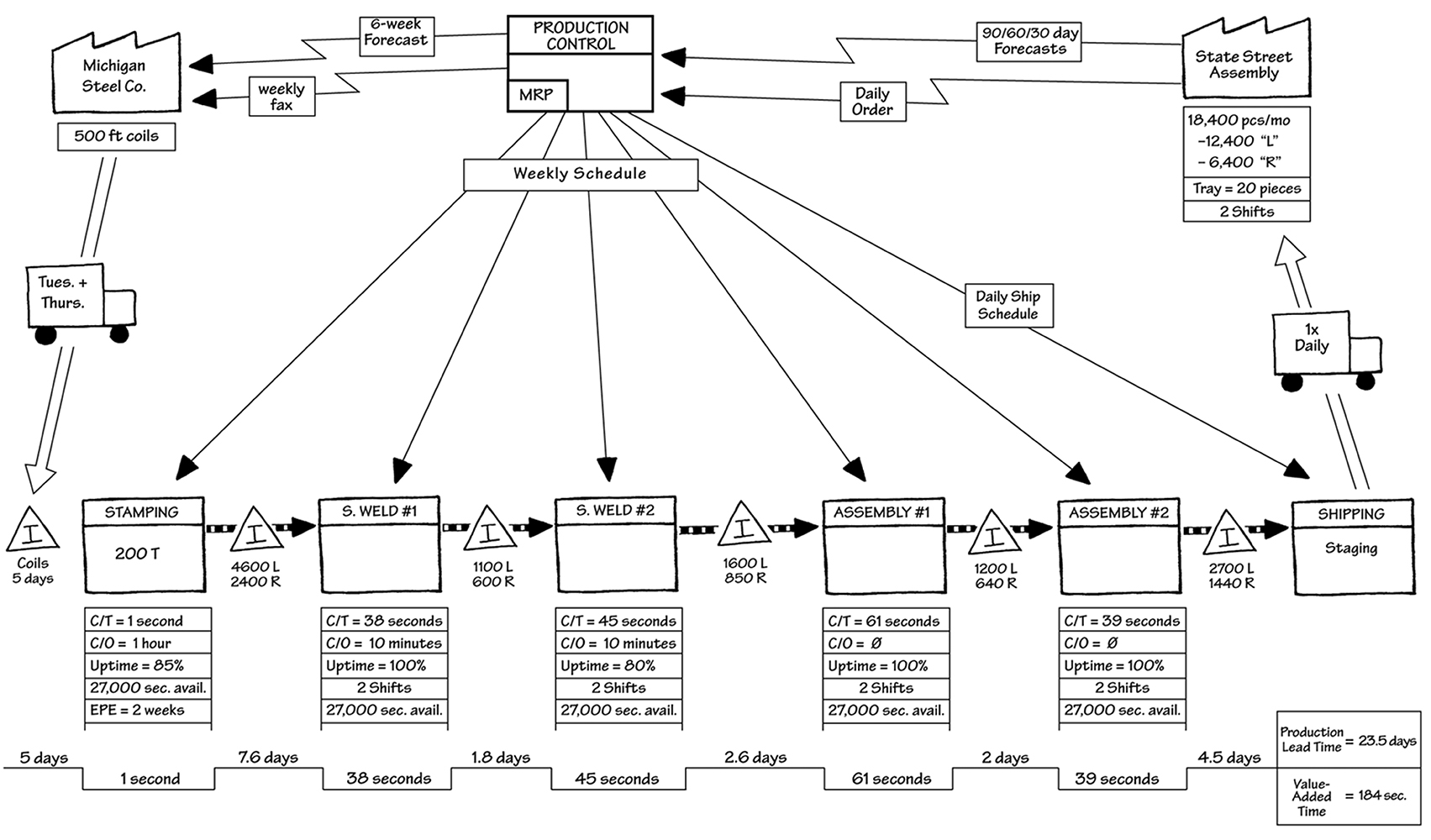

T O T O T A T A L L V V A A L U L U E E S S T T R RE E A AM M. PART I: GETTING STARTED 3. Value-stream mapping is a pencil and paper tool that helps you to see and understand the flow of material and information as a product makes its way through the value stream. What we mean by value-stream mapping is simple: Follow a product's production.

10 Easy Steps to Complete a Value Stream Map Value stream mapping, Printing and binding, Map

Value-stream mapping (VSM) is a fundamental lean practice that involves diagraming a value stream, which includes all the actions (value-creating and nonvalue-creating) needed to move a product or service from raw material to the arms of the customer, including the material and information flow. Lean practitioners use the process and the.

Project Value Stream Mapping MudaMasters

4. Conclusion. The value stream is a series of processes and activities that a business model goes through to add value to the inputs and deliver products to customers. Value stream mapping symbols allow you to create a map that identifies potential gaps for reducing waste of both material and effort. A value stream map is a lean tool that.

Value Stream Mapping Template Excel Free

Value stream maps depict the steps in the process of producing a product or delivering a service, where the interfaces are between activities, loop backs, the time involved in and between process steps, and the queues where work is waiting. Figure 2 shows an example of a classic value stream map. Figure 2. Example value stream map for development.

Value stream mapping uitgelegd Lucidchart Blog

Werkwijze en Value Stream Mapping voorbeeld. Voordat de huidige situatie in kaart wordt gebracht, moet eerst het doel van de analyse worden vastgesteld; bijvoorbeeld het verlagen van de doorlooptijd of het verhogen van de kwaliteit. Het is daarbij belangrijk dat de doelen acceptabel zijn voor de medewerkers. Vervolgens wordt de klantwaarde per.

How to Do Value Stream Mapping in Excel?

Also called: value stream analysis, lean process mapping. Value stream mapping (VSM) is defined as a lean tool that employs a flowchart documenting every step in the process. Many lean practitioners see VSM as a fundamental tool to identify waste, reduce process cycle times, and implement process improvement. VSM is a workplace efficiency tool.